Model No.︰JH-EXL1414

Brand Name︰Shenzhen Ju Hong

Country of Origin︰China

Unit Price︰-

Minimum Order︰25 kg

Supply impact modified PC Shenzhen Ju Hong JH-EXL1414T transparent grade low temperature super toughness grade

Introduction to PC plastics /PC plastics

(polycarbonate)

English Name: Polycarbonate

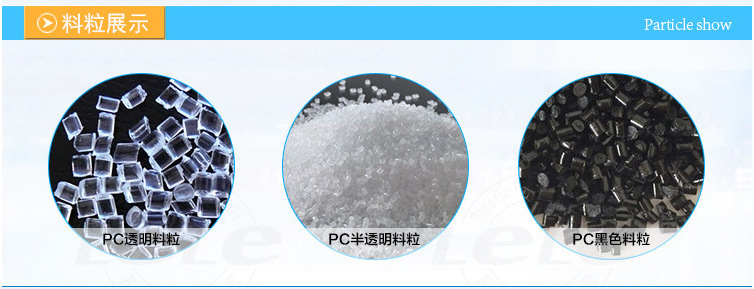

Polycarbonate is a common material. Because of its colourless transparency and excellent impact resistance, the common daily applications are CD-ROM, glasses, water bottles, bullet-proof glass, goggles, bank bullet-proof glass, car headlights, animal cages, pet cages, etc.

Polycarbonate PC is also a kind of material used in notebook computer shell. Its raw material is petroleum. After processing by polyester chip factory, it becomes particulate matter of polyester chip. After processing by plastic factory, it becomes finished product. From a practical point of view, its heat dissipation performance is better than ABS plastic, and its heat dispersion is more uniform.

The most notable use of this material is FUJITSU, which is used in many models and in all cases. No matter from the surface or touch, PC-GF material feels like metal. If there is no sign in the notebook computer, it may be considered as an alloy if it is not carefully observed from the outside.

Polycarbonate is also used to make lunar astronauts helmet masks. Apple Corp's iPod music player and iBook laptop shell are also made of polycarbonate.

Because of its clarity and resilience, producers and purchasers of food stocks prefer polycarbonate fibers. When compared with silica glass, polycarbonate fibers are lightweight and highly brittle. Polycarbonate fibers are mostly used for disposable plastic bottles and reuse of plastic water bottles.

Chemical properties of /PC plastics

Polycarbonate is resistant to weak acid and neutral oil.

Polycarbonate is resistant to UV light and alkali resistance.

Physical properties of /PC plastics

Specific gravity: 1.18-1.20 g/cubic centimeter forming shrinkage: 0.5-0.8% forming temperature: 230-320 C drying conditions: 110-120 C 8 hours can be used at - 60-120 C for a long time.

The material has high impact strength, good dimensional stability, colorless transparency, good coloring, electrical insulation, corrosion resistance and wear resistance, but poor self-lubrication, stress cracking tendency, easy hydrolysis at high temperature and poor compatibility with other resins. It is suitable for making small parts of instrument, insulating transparent parts and impact resistant parts.

Material properties 1. amorphous material, good thermal stability, wide molding temperature range and poor fluidity. Hygroscopicity is small but sensitive to water and must be dried. Molding shrinkage is small, melt cracking and stress concentration are easy to occur, so the forming conditions should be strictly controlled, and the plastic parts must be annealed.

2. plastic parts with high melting temperature and high viscosity, greater than 200g, should be heated with extended nozzles.

3. Plastic fluidity is poor. The casting system of the mould should be rough and short. It is appropriate to set up a cold material well. The gate should be large and the mould should be heated.

4. too low material temperature will result in lack of material, plastic parts without luster, high material temperature, overflow edge and blister. The mold temperature is low, the shrinkage rate is small, the elongation is small, the impact strength is low, the bending resistance, compressive strength and tensile strength are low. When the mold temperature exceeds 120 degrees, the plastic parts are cooled slowly and easy to form and mold.

5. plastic parts wall should not be too thick, should be uniform, avoid sharp corners and gaps.

Material properties of /PC plastics

1. High strength, tensile strength 69MPa and flexural strength 96MPa.

Second, high temperature, long term use can withstand 130 degrees Celsius temperature environment.

2. Good transparency and no toxicity.

4. Raw material color matching and surface coating are not as good as ABs.

Pc should choose high mobility brand. It is suitable for mobile phones and used in harsh environments.

Processing technology /PC plastic

Plastics treatment

PC has a higher water absorption rate. It must be preheated and dried before processing. Pure PC is dried at 120 C. Modified PC is usually dried at 110 C for more than 4 hours. The drying time should not exceed 10 hours. Generally, the air extrusion method can be used to judge whether the drying is enough.

The proportion of recycled materials can reach 20%. In some cases, recycled materials can be used 100%, and the actual weight depends on the quality requirements of the products. Recycled materials can not be mixed with different color masterbatch at the same time, otherwise it will seriously damage the nature of the finished product.

Selection of injection molding machine

Because of cost and other reasons, PC products now use more modified materials, especially electrical products, but also need to increase fire resistance. In the process of forming flame-retardant PC and other plastic alloy products, the requirement of plasticizing system of injection moulding machine is good mixing and corrosion resistance. Conventional plasticizing screw is difficult to achieve. When choosing and purchasing, it must be certain. It should be explained in advance. Ramada has a dedicated PC screw for customers to choose.

Mold and gate design

Common mold temperature is 80-100 C, plus glass fiber is 100-130 C, small products can be used needle gate, gate depth should be 70% of the thickest part, other gates have ring and rectangular.

The larger the gate, the better it will be to reduce the excessive shearing of the plastic. The depth of the vent should be less than 0.03-0.06mm and the flow path should be as short and round as possible. The release angle is generally about 30 '-1 degrees.

Melt Temperature

The method of air injection can be used to determine the processing temperature. The general PC processing temperature is 270-320 C, and some modified or low molecular weight PC is 230-270 C.

Injection speed

It is often used for injection molding, such as electric switch. It is usually slow to rapid prototyping.

Backpressure

The backpressure of 10bar can be reduced appropriately without the presence of air marks and mixed colors.

Detained time

If the residence time is too long at high temperature, the material will be degraded and CO2 will become yellow. Do not use LDPE, POM, ABS or PA to clean the cylinder. Use PS to clean up.

Supply impact modified PC Shenzhen Ju Hong JH-EXL1414T transparent grade low temperature super toughness grade

Introduction to PC plastics /PC plastics

(polycarbonate)

English Name: Polycarbonate

Polycarbonate is a common material. Because of its colourless transparency and excellent impact resistance, the common daily applications are CD-ROM, glasses, water bottles, bullet-proof glass, goggles, bank bullet-proof glass, car headlights, animal cages, pet cages, etc.

Polycarbonate PC is also a kind of material used in notebook computer shell. Its raw material is petroleum. After processing by polyester chip factory, it becomes particulate matter of polyester chip. After processing by plastic factory, it becomes finished product. From a practical point of view, its heat dissipation performance is better than ABS plastic, and its heat dispersion is more uniform.

The most notable use of this material is FUJITSU, which is used in many models and in all cases. No matter from the surface or touch, PC-GF material feels like metal. If there is no sign in the notebook computer, it may be considered as an alloy if it is not carefully observed from the outside.

Polycarbonate is also used to make lunar astronauts helmet masks. Apple Corp's iPod music player and iBook laptop shell are also made of polycarbonate.

Because of its clarity and resilience, producers and purchasers of food stocks prefer polycarbonate fibers. When compared with silica glass, polycarbonate fibers are lightweight and highly brittle. Polycarbonate fibers are mostly used for disposable plastic bottles and reuse of plastic water bottles.

Chemical properties of /PC plastics

Polycarbonate is resistant to weak acid and neutral oil.

Polycarbonate is resistant to UV light and alkali resistance.

Physical properties of /PC plastics

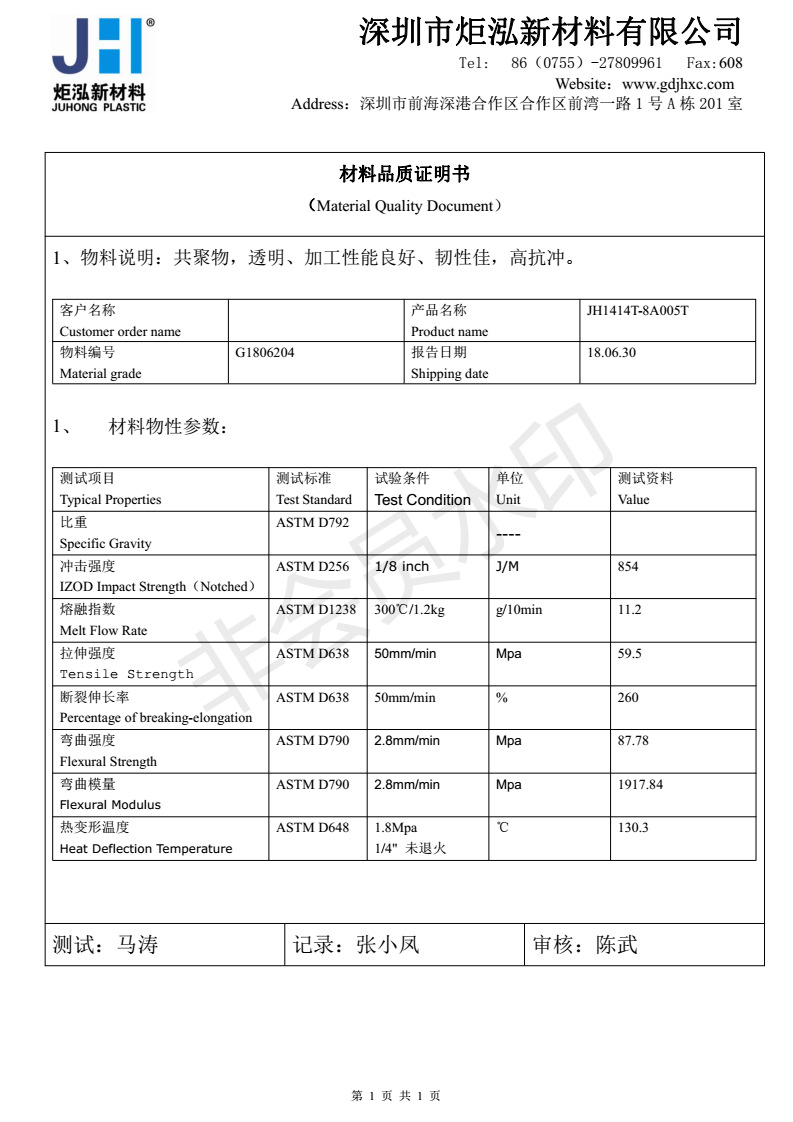

Specific gravity: 1.18-1.20 g/cubic centimeter forming shrinkage: 0.5-0.8% forming temperature: 230-320 C drying conditions: 110-120 C 8 hours can be used at - 60-120 C for a long time.

The material has high impact strength, good dimensional stability, colorless transparency, good coloring, electrical insulation, corrosion resistance and wear resistance, but poor self-lubrication, stress cracking tendency, easy hydrolysis at high temperature and poor compatibility with other resins. It is suitable for making small parts of instrument, insulating transparent parts and impact resistant parts.

Material properties 1. amorphous material, good thermal stability, wide molding temperature range and poor fluidity. Hygroscopicity is small but sensitive to water and must be dried. Molding shrinkage is small, melt cracking and stress concentration are easy to occur, so the forming conditions should be strictly controlled, and the plastic parts must be annealed.

2. plastic parts with high melting temperature and high viscosity, greater than 200g, should be heated with extended nozzles.

3. Plastic fluidity is poor. The casting system of the mould should be rough and short. It is appropriate to set up a cold material well. The gate should be large and the mould should be heated.

4. too low material temperature will result in lack of material, plastic parts without luster, high material temperature, overflow edge and blister. The mold temperature is low, the shrinkage rate is small, the elongation is small, the impact strength is low, the bending resistance, compressive strength and tensile strength are low.When the mold temperature exceeds 120 degrees, the plastic parts are cooled slowly and easy to form and mold.

5. plastic parts wall should not be too thick, should be uniform, avoid sharp corners and gaps.

Material properties of /PC plastics

1. High strength, tensile strength 69MPa and flexural strength 96MPa.

Second, high temperature, long term use can withstand 130 degrees Celsius temperature environment.

2. Good transparency and no toxicity.

4. Raw material color matching and surface coating are not as good as ABs.

Pc should choose high mobility brand. It is suitable for mobile phones and used in harsh environments.

Processing technology /PC plastic

Plastics treatment

PC has a higher water absorption rate. It must be preheated and dried before processing. Pure PC is dried at 120 C. Modified PC is usually dried at 110 C for more than 4 hours. The drying time should not exceed 10 hours. Generally, the air extrusion method can be used to judge whether the drying is enough.

The proportion of recycled materials can reach 20%. In some cases, recycled materials can be used 100%, and the actual weight depends on the quality requirements of the products. Recycled materials can not be mixed with different color masterbatch at the same time, otherwise it will seriously damage the nature of the finished product.

Selection of injection molding machine

Because of cost and other reasons, PC products now use more modified materials, especially electrical products, but also need to increase fire resistance. In the process of forming flame-retardant PC and other plastic alloy products, the requirement of plasticizing system of injection moulding machine is good mixing and corrosion resistance. Conventional plasticizing screw is difficult to achieve. When choosing and purchasing, it must be certain. It should be explained in advance. Ramada has a dedicated PC screw for customers to choose.

Mold and gate design

Common mold temperature is 80-100 C, plus glass fiber is 100-130 C, small products can be used needle gate, gate depth should be 70% of the thickest part, other gates have ring and rectangular.

The larger the gate, the better it will be to reduce the excessive shearing of the plastic. The depth of the vent should be less than 0.03-0.06mm and the flow path should be as short and round as possible. The release angle is generally about 30 '-1 degrees.

Melt Temperature

The method of air injection can be used to determine the processing temperature.The general PC processing temperature is 270-320 C, and some modified or low molecular weight PC is 230-270 C.

Injection speed

It is often used for injection molding, such as electric switch. It is usually slow to rapid prototyping.

Backpressure

The backpressure of 10bar can be reduced appropriately without the presence of air marks and mixed colors.

Detained time

If the residence time is too long at high temperature, the material will be degraded and CO2 will become yellow. Do not use LDPE, POM, ABS or PA to clean the cylinder. Use PS to clean up.

Price Terms︰ FOB Guangdong

Payment Terms︰ TT

Packing︰ 25kg

Lead Time︰ 3day

SKU︰ 500T

Standards Certificate︰ SGS REACH ROSH

specifications︰ PC/ Shenzhen Ju Hong /JH-EXL1414 super tough and cold resistant modified high impact UV resistant electronic appliances

Advantages︰

Main advantages

1. It has high strength and elasticity coefficient, high impact strength and wide use temperature range.

2. High transparency and free coloring.

3. Low shrinkage and good dimensional stability.

4. Good fatigue resistance.

5. Good weather resistance.

6. Excellent electrical characteristics.

7, tasteless and odorless harmless to human body is in line with health and safety.